Our Solutions

Filter Technology

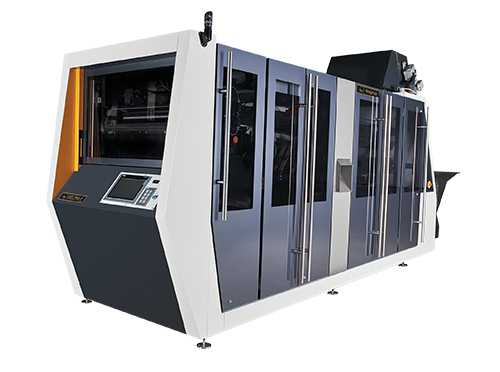

Polaris P

This new machine has unique features distinguishing it from other solutions which are on the market. Polaris P enables efficient production of a wide range of paper filter specifications with parameters comparable to acetate product, characterised by high stability and similar pressure drop. Being of modular design, the new platform enables the installation of further functional elements, allowing the manufacture of filters with capsule, cardboard tubes, granules, and other additives in a single pass. The application of liquids by using advanced SPI fluid application systems gives further opportunities for changing the filter flavour, performance, and sensation parameters.

Paper filters manufactured using Polaris P machine are characterized by the same quality and efficiency as acetate filters and are implemented in both traditional and new generation products (HNB/THP). This is the real “game changer” on the market.

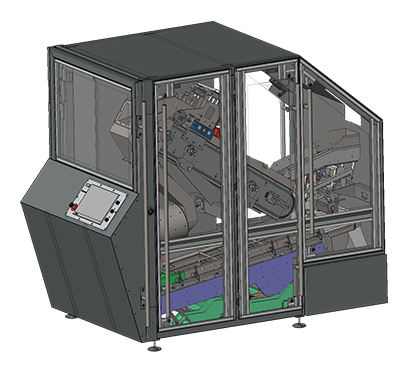

Solaris

It is the innovative combiner for the production of multi-filters and HNB/THP product, allowing great freedom of design, using different material compositions. It facilitates effective product development of traditional and new generation products (HNB/THP) as well as easy and fast implementation into regular high-volume production. Solaris can process individual segments ranging from 5-46 mm in length, irrespective of their diameter, for both symmetric and asymmetric product compositions. Specially designed suction free, in-line technology allows the processing and handling of a variety of base materials for making a wide range of dual, triple, and quadruple product compositions: recess, cardboard tube (HAT), NWA, plastic shaped tubes, channel ventilation, thread and granule application can be easily manufactured.

Solaris is highly effective technology platform, which redefines the art of filter and HNB/THP combining.

Polaris CIM

Discover Polaris with Capsule Insertion Module (CIM)—a groundbreaking solution that sets a new benchmark in filter manufacturing. For the first time in history, capsule insertion technology no longer limits the nominal speed of filter makers, ensuring up to 500 meters per minute with unmatched precision. Polaris enables the insertion of one, two, or even multiple capsules without compromising speed or product quality. Each capsule is handled with extreme care through a gentle, non-destructive process that guarantees consistency and reliability. The system offers high insertion accuracy, maintaining capsule position and repeatability, while minimizing waste to below 2%. Designed for flexibility and efficiency, Polaris empowers manufacturers to expand capabilities and meet market demands with confidence.

SCTM

ITM Spiral Cardboard Tube Maker has been designed to produce spiral cardboard tubes made of biodegradable 3 plies of paper strips with wide range of product diameter and length, all in one automatic and continuous process, according to the required specification. Its modular design allows to adjust output capacity according to the product demands. Each module is capable to produce spiral cardboard tubes with speed of 85 m/min. Spiral Cardboard tube is formed on mandrel with very high roundness parameter and cut, precisely in unique cutting head in one process. Paper delivery and tube forming are oriented vertically which ensures high and effective output from square meter. Tube maker are equipped with the newest control equipment and continuously monitoring each part of process and product quality.

Tubes produced on the SCTM can be used in traditional or next generation tobacco product categories, including the replacement of HAT product in paper filters due to smallest available tube diameter on the market.

Reclaiming

SNUS Reclaiming

This is one of the latest solutions of ITM, which is designed as to accept waste from snus making machine to recover snus product from rejected pouches and optionally return it back to production process.

Specially dedicated Cylindrical Opening Unit extending separation time to increase recovery rate. Cutting process is specially created to maximally avoid generation of fabric snips assuring highest cleanness of the final product. Machine is equipped with single connection point for de-dusting to minimize dust propagation. Pouches rejected in cans shall be manually transferred to the machine hopper.

Snus machine has been tested with today’s market demands for flexibility and a variety of different brands and associated blend variations in mind. Additionally, the need to operate efficiently, often necessitating cleaning the reclaimer between brands to avoid cross contamination has also been incorporated.

Delphi 2

This is a globally proven, modern tobacco recovery system designed to process production waste cigarettes of wide specification range, with the advantages of an improved recovery rate and the highest quality of recovered tobacco. With integrated infeed separation, new aligning system and a very gentle, delicate, opening process, the Dephi 2provides a process combination ready for cigarettes, including capsule cigarettes, and next generation products. Effective, efficient and robust, the innovative design of Delphi 2 ensures that no filter plug components are released during the reclaim process, ensuring minimal contamination of the recovered tobacco.

Delphini MAX

It is a compact reclaiming system recovering tobacco from waste cigarettes with the highest efficiency of over 95%, delivering the best quality tobacco for add-back. The machine can process a broad variety of cigarettes from super slim to king size types, including special filters, and has been designed as a portable unit to serve any type of maker available on the market. The Delphini system keeps the recovery process in the Secondary department, with easy and quick relocation possible between Make Pack groups, using plug’n’play principles and no electrical interface with other machines. In addition, the machine ensures full tobacco traceability and eliminates the risk of cross contamination between brands.

The main benefits of the solution include:

- On-line, portable unit without wire connection with the maker,

- Processing capability for cigarettes with charcoal, flavors and capsules,

- Controlled and precise adding back process.